Paint Mask barcode labels for production tracking

Tracking through production

Most manufacturing companies must adhere to their customers' stringent quality requirements and be able to track and trace each part during the manufacturing process.

With products going through many different processes during manufacture the paint shop creates the biggest problem for parts marking because any asset label or marking on an item will be covered in paint and thus the information is un-readable further down the production line.

Dantech, a well established label company specialising in labelling for manufacturing and storage in industrial harsh environments, can solve this problem with their special removable paint mask asset labels.

A clear laminate on top of the printed information label can easily be removed once the product emerges from the drying oven (labels will withstand temperatures up to 200° C short term) by simply peeling the laminate away and the tracking details, barcode, etc. emerges clean and ready to scan - an ideal solution for tracking a product through the production process.

The paint mask asset labels have sub-surface printing and will therefore withstand many chemicals and abrasion. Information such as sequential numbering and barcode are easily included in the printing.

Labels can also be supplied with a special fluoropolymer laminate (similar to Teflon© coating) which will resist paint - after painting simply pick off the paint and the label information is visible ready to be scanned.

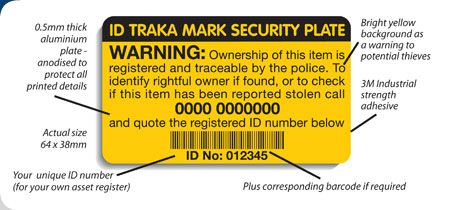

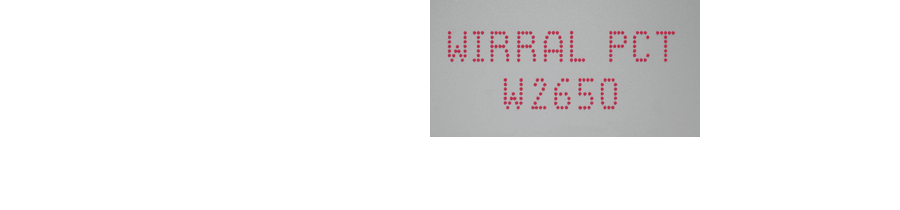

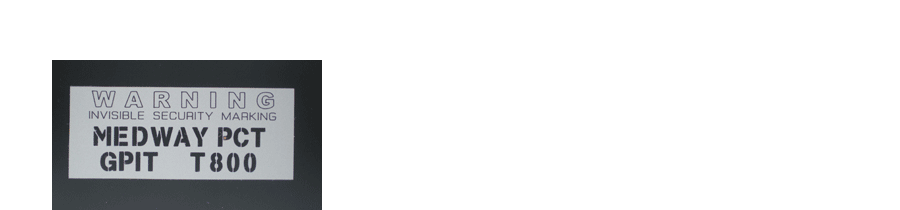

Dantech is an acknowledged supplier for more than 15 years to both industry, government departments and the educational and health sector of security marking products, asset labels and security labels.

With a high reputation built over the years on customer satisfaction Dantech can provide help and advice with your marking requirements,contact Dantech on 01354 688 488 for free and unbiased help and advice.

Published on Tuesday 30th November 1999